SECTIONAL GARAGE DOORS

SECTIONAL GARAGE DOORS

General information about sectional garage doors

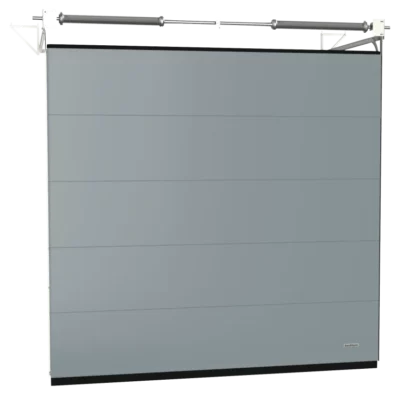

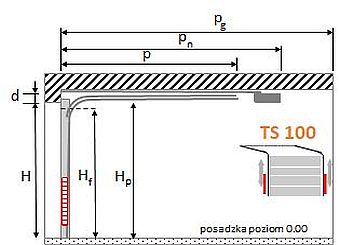

The Beditom sectional garage door is designed for installation in door openings in single-family buildings. It is constructed of vertical and horizontal guides suspended from the ceiling and a steel insulated door casing. The door structure is made of galvanized steel elements.

The door is sealed around the entire perimeter and between the segments. The door casing segments are insulated with freon-free polyurethane foam, with a thickness: 40 mm. Doors are available in manual or automatic versions.

PRODUCTS

Garage doors for your home

TECHNICAL INFORMATION

Door casing

The garage door casing is made of 40 mm thick segments (panels) made of galvanized steel sheet with an insulating core made of CFC-free polyurethane foam. The shape of the segment edge is specially profiled to prevent fingers from being pinched. At the ends of the segments, galvanized steel reinforcing fittings are mounted, to which elements connecting the segments are installed, such as steel side hinges with bearing-mounted nylon rollers enabling the door to be guided in the guides, and for each door width, central hinges ensuring the appropriate stiffness of the garage door casing. The doors are equipped with a system of durable, flexible, and weather-resistant seals, which are placed around the entire perimeter of the door and between the segments. The seal between the top panel and the lintel is provided by a seal mounted to the top panel or to the lintel. A seal made of a special modified EPDM material is installed in the bottom panel, adhering to the ground.

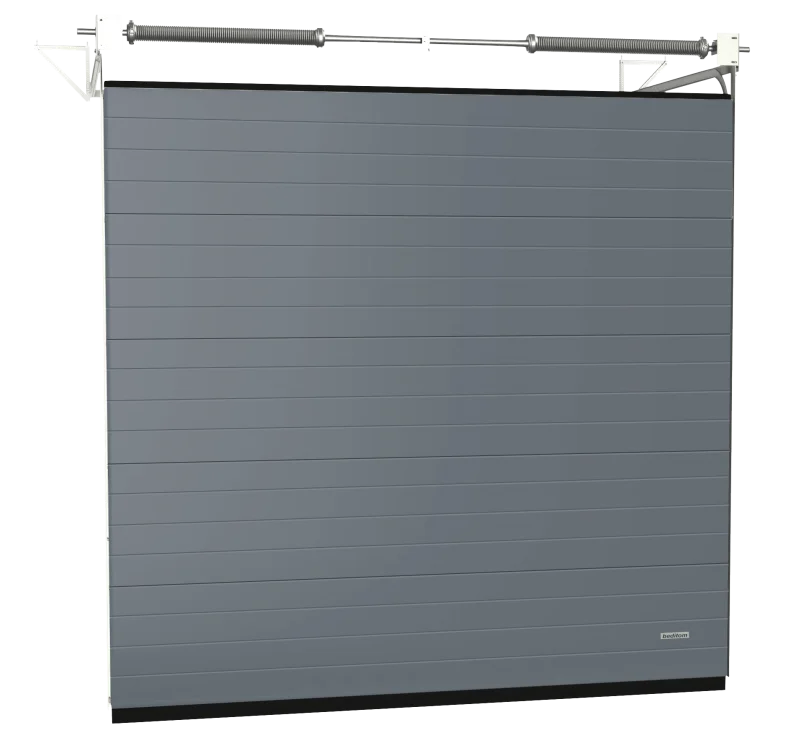

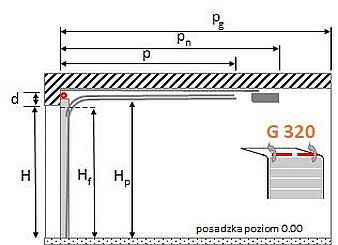

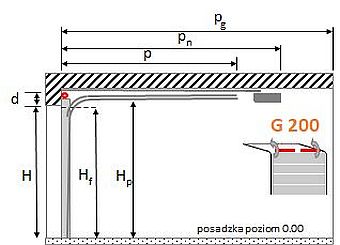

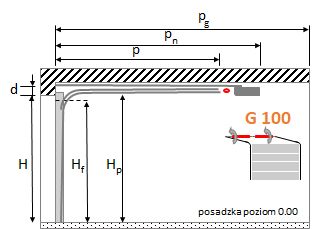

Guides

Made of profiled galvanized steel elements that prevent the nylon rollers from sliding out or falling out. The vertical guides are equipped with integrated side seals, which, together with the bottom and top seals of the garage door, create a perimeter seal for the closed position. Horizontal guides equipped with a bracing profile and adapted to suspensions selected according to the size of the door and type of structure to ensure stability and rigidity during use.

The doors are available in two balancing systems.

The first torsion spring system for guides mounted on a shaft in the lintel or on the back of horizontal guides. Torsion springs are standardly designed for at least 20,000 cycles and are made in a galvanized version. It is possible to manufacture springs for a larger number of cycles, e.g., 50,000 or 100,000 cycles. Spring break protection mechanisms (MZS) as standard.

The second system of tension springs for guides is mounted along the vertical guides in the amount of 2 to 3 pieces per side, made in a galvanized version and designed for 25,000 cycles.